Why Choose IFAB to Design your Dairy Plant?

From pasteurization to secondary processes for cream, butter, cheese, and yogurt, your dairy products need a process that is hygienic, manages waste efficiently, and ensures maximum temperature control.

We understand the complications in designing a dairy facility that meets national and international food safety regulatory requirements. Plus we love cheese!

Our Experience Designing Dairy Plants

Not all cooks have the same experience, and not all engineering companies have designed food processing plants.

When you’re investing in a strategic project for your food company, you don’t want a partner that is trying a new recipe with your budget.

We have worked with every type of food processing company from meats, to cheeses, and anything else to fill your charcuterie board. Through our experience working with companies like yours, we have developed expertise in creating hygienic, optimized spaces that work.

Dairy Processing

Features in past designs for dairy processing include:

- Hygienic design of building and dairy processing lines

- Pasteurization processes

- Separation using membrane filtration and spray drying

- Secondary processes for cream, butter, cheese, and yogurt

- Management of the thermal envelope for maximum temperature control

- Facility waste and water management

Portfolio: Dairy

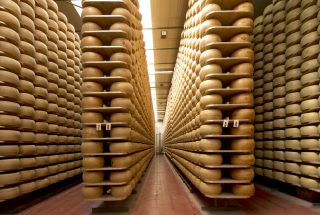

Cheese requires specific humidity, temperature and patience. We have helped clients create their facilities.

Cheese Producer

Manitoba

Worked with a cheese manufacturer to optimize the facility for future growth by consolidating electrical requirements into a single mechanical and electrical room. Work included design, project management, and consultations for future plant growth.

Goat Cheese Producer

Ontario

Provided services from concept through construction for the expansion of goat cheese production.